Compact Flatbed Cutting Plotter

Rapidly bringing ideas into shape

Nagano, Japan (February 2, 2015)

Mimaki Engineering Co., Ltd., a global industry leader and manufacturer of wide-format inkjet printers and cutting plotters, announced today that it will launch a new compact flatbed cutting plotter, model CFL-605RT, in February, 2015. The CFL-605RT supports material sizes up to A2 extra and has a variety of functions including eccentric, tangential, and reciprocating cuttings and creasing.

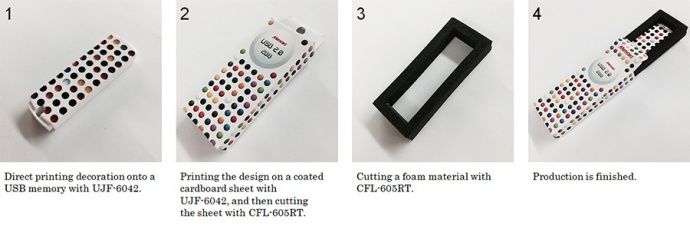

The use of digital on-demand UV inkjet printing has increased for creating original customized goods in response to an increase in high-mix low-volume demands in the market. The new CFL-605RT is designed with Mimaki’s well-established technology, and supports on-demand production by multiple functions, including cutting and creasing. The CFL-605RT delivers efficient sample and package production. The combination of the CFL-605RT and LED UV inkjet printer UJF-6042 delivers the whole process for the original goods production of samples or small-lot orders by printing onto goods and package materials, and cutting cushioning materials.

* The UJF-6042 is sold separately.

◎Product outlines

- The multifunction plotter strongly supports digital on-demand production

・Eccentric cut

・Tangential cut

・Reciprocating cut

・Creasing - The combination of CFL-605RT and UJF-6042 achieves package fabrication on-demand

Use in combination with the UJF-6042 achieves on-demand production of the original goods by providing the whole production process, including printing onto goods and packages, and cutting of cushioning materials.

* UJF-6042 is sold separately.

◎Main features

1. On-demand production supporting functions are packed in one compact plotter unit!

1) Eccentric cutter

Maximum cutting thickness: 1 mm *1

Materials are properly cut with an optimal downforce setting between 30 and 1,000 g.

2) Tangential cutter

Maximum cutting thickness: 2 mm *1

The tangential cutter accepts material thickness of up to 2 mm with high downforce pressure. Reflective vinyl or rubber sheets are also applicable.

3) Reciprocating cutter

Maximum cutting thickness: 10 mm *1

A blade cuts thick materials such as foam or cardboard by vertical reciprocating motion.

4) Creasing roller

The roller creases materials and enables the creation of a perfect package. Downforce pressures are adjustable from 500 to 1,500 g depending on the material.

*1: Please note that an applicable range of cutting thickness may slightly vary depending on materials.

2. The combination of CFL-605RT and UJF-6042 broadens the range of on-demand package production.

Conventionally, there were many work processes to create the package that suits a product. You would ask an outside contractor to create the package, and it would take a long time to complete the work because of misunderstandings, distance, time differences, etc.

The combination of CFL-605RT and UJF-6042 offers a total solution not only for printing on a product but also for the design and creation of product/cushion packaging. This combination delivers effective high-mix low-volume production and significantly shortens the lead time for prototype creation and small lot production by on-demand fabrication.

LED UV flatbed inkjet printer UJF-6042

The UJF-6042 is a flatbed UV inkjet printer and capable of printing on objects as well as on the package materials up to A2 size.

For example, printing on USB memory and creating packaging

◎Specifications

| Item | CFL-605RT | |

|---|---|---|

| Working range | 610 mm × 510 mm | |

| Driving method | X/Y/Z/Θ 4 axes: DC servo motor | |

| Maximum working speed | XY: 423 mm/s (45° angle direction) Z: 30 mm/s | |

| Static accuracy | Repeatability | 0.2 mm or lower (Material shrinkage is ignored) |

| Distance accuracy | Moving distance × ±0.2% or lower or ±0.1 mm or lower Larger value is applied |

|

| Original repetition accuracy |

0.1 mm or lower | |

| Material thickness | Eccentric cutter | 1mm or lower *1 |

| Tangential cutter | 2 mm or lower *1 | |

| Reciprocating cutter | 10 mm or lower *1 | |

| Material holding method | Air suctioning by a vacuum unit | |

| Receive buffer | 30 MB | |

| Command | MGL-IIc3 | |

| Interface | USB 2.0 (High Speed), RS-232C, Ethernet | |

| Operational environment | Temperature: 5 °C–35 °C, 35%–75% RH (Non-condensing) Guaranteed humidity range for an accurate operation: 12 °C–25 °C, 45%–65% RH (Non-condensing) |

|

| Power specification | Single phase AC 100–120 V/200–240 V, 50/60 Hz | |

| Power consumption | 500 W or lower | |

| Dimensions (W × D × H) | 1,320 mm × 1,045 mm × 1,100 mm | |

| Weight | 97 kg (Blower, 20 kg, included) | |

Please note:

*1: An applicable range of cutting thickness may slightly vary depending on materials.

*2: In an effort to improve our product, specifications, designs, dimensions, and other data are subject to change without notice.

◎Contact

Mimaki Engineering Co., Ltd.

Global Marketing Department

Postal code: 389-0512

Address: 2182-3 Otsu Shigeno Tomi, Nagano, Japan

Tel: +81-(0)268-64-2281, Fax: +81-(0)268-64-2285