MIMAKI SINGAPORE PTE. LTD.

Product

Find a product by the product category

Find product by application

Inkjet Printer

Cutting Plotter / Vinyl Cutter

Laminator

3D Printer

NewsNews list

Case StudyCase Study list

From Life-Size Panels to Seals and Stickers: Size-Flexible Applications Expand In-House Production and Boost Repeat Orders: REC Corp.Mimaki user stories

Challenges

Improvements

They use a laser cutting machine for material cutting, but when cutting life-size panels made of aluminum composite panels, the cut edges melted due to heat, resulting in an unsightly finish. Additionally, they handle other materials that laser cutting struggles with, such as thin sheet films and styrene boards. They were searching for a cutting plotter capable of handling these materials.

CFX does not burn the cross section like laser cut, and a satisfactory finish is obtained.Since it has a dragonfly reading function, there is no slight positional deviation when cutting.Therefore, it is also useful for cutting small printed matters such as seals, stickers, and product mounting paper. The range of in-house manufacturing has expanded and it has become possible to meet various requests.

Product installed

Challenges

Improvements

They use a laser cutting machine for material cutting, but when cutting life-size panels made of aluminum composite panels, the cut edges melted due to heat, resulting in an unsightly finish. Additionally, they handle other materials that laser cutting struggles with, such as thin sheet films and styrene boards. They were searching for a cutting plotter capable of handling these materials.

CFX does not burn the cross section like laser cut, and a satisfactory finish is obtained.Since it has a dragonfly reading function, there is no slight positional deviation when cutting.Therefore, it is also useful for cutting small printed matters such as seals, stickers, and product mounting paper. The range of in-house manufacturing has expanded and it has become possible to meet various requests.

Product installed

The Proven Performance of the "CJV200" Entry Model, Combining High-Quality Output and Ease of Use:SAN GRAPHICA Inc.Mimaki user stories

Challenges

Improvements

At SAN GRAPHICA Inc., while the "CJV300" had delivered high-quality printing, the expanding range of production materials necessitated more stable high-resolution output and improved workflow efficiency. Additionally, the ability to operate within limited installation space and the ease of operation and manageability even with a small staff were key points when considering equipment upgrades.

The introduction of the "CJV200" maintains the same high image quality while further improving color reproduction and detail stability. Its compact size and simple operation allow it to fit seamlessly into any workspace, streamlining daily tasks. Furthermore, low-odor ink and a system for monitoring operational status create an environment where even small teams can operate with confidence.

Product installed

Challenges

Improvements

At SAN GRAPHICA Inc., while the "CJV300" had delivered high-quality printing, the expanding range of production materials necessitated more stable high-resolution output and improved workflow efficiency. Additionally, the ability to operate within limited installation space and the ease of operation and manageability even with a small staff were key points when considering equipment upgrades.

The introduction of the "CJV200" maintains the same high image quality while further improving color reproduction and detail stability. Its compact size and simple operation allow it to fit seamlessly into any workspace, streamlining daily tasks. Furthermore, low-odor ink and a system for monitoring operational status create an environment where even small teams can operate with confidence.

Product installed

Collaboration

Efforts of Mimaki

Support ski jumper Sara Takanashi with merchandise made using UV-DTF printers!

We printed the "JUMP for the Earth PROJECT" logo on a ready-made tumbler using the UV-DTF printer "UJV300DTF-75" and presented them to Sara Takanashi.

Product used

Collaboration

Efforts of Mimaki

Support ski jumper Sara Takanashi with merchandise made using UV-DTF printers!

We printed the "JUMP for the Earth PROJECT" logo on a ready-made tumbler using the UV-DTF printer "UJV300DTF-75" and presented them to Sara Takanashi.

Product used

From Life-Size Panels to Seals and Stickers: Size-Flexible Applications Expand In-House Production and Boost Repeat Orders: REC Corp.Mimaki user stories

Challenges

Improvements

They use a laser cutting machine for material cutting, but when cutting life-size panels made of aluminum composite panels, the cut edges melted due to heat, resulting in an unsightly finish. Additionally, they handle other materials that laser cutting struggles with, such as thin sheet films and styrene boards. They were searching for a cutting plotter capable of handling these materials.

CFX does not burn the cross section like laser cut, and a satisfactory finish is obtained.Since it has a dragonfly reading function, there is no slight positional deviation when cutting.Therefore, it is also useful for cutting small printed matters such as seals, stickers, and product mounting paper. The range of in-house manufacturing has expanded and it has become possible to meet various requests.

Product installed

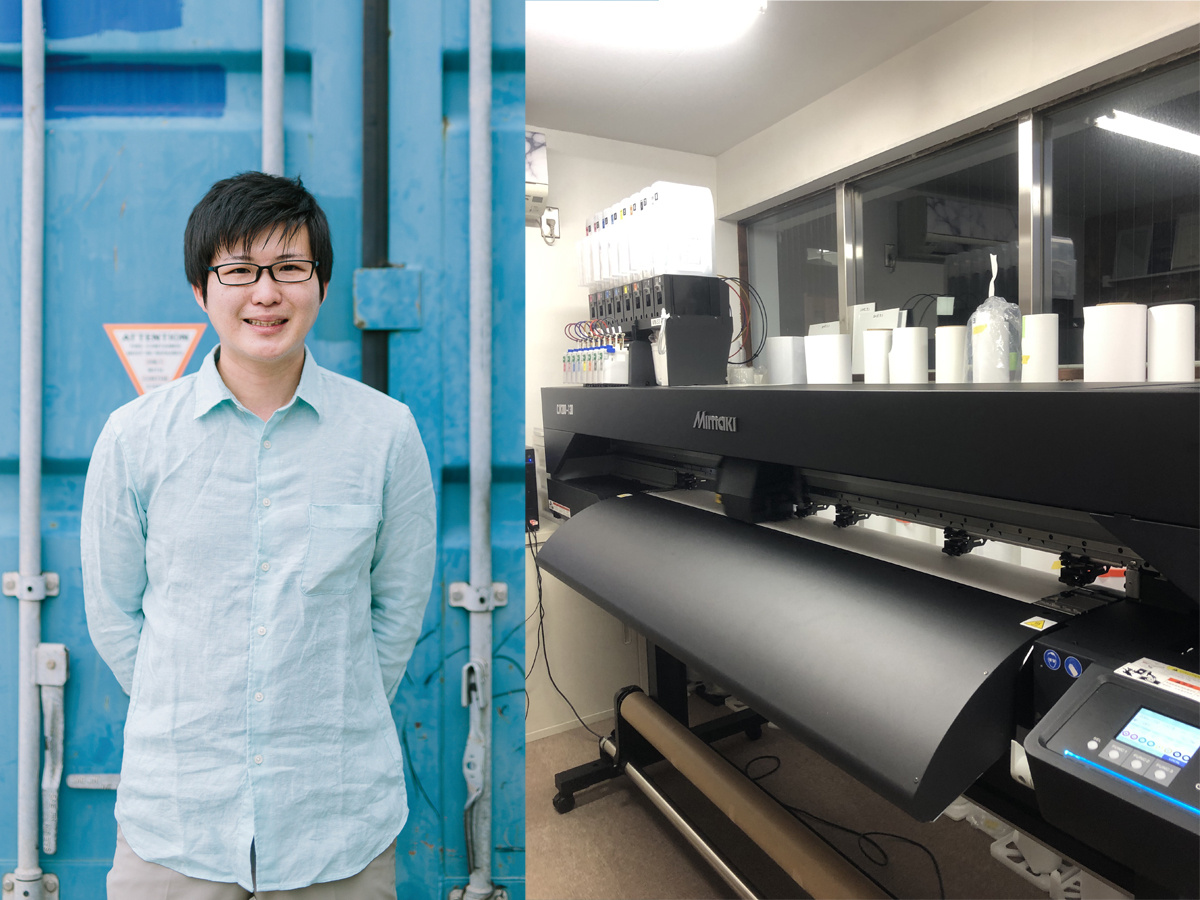

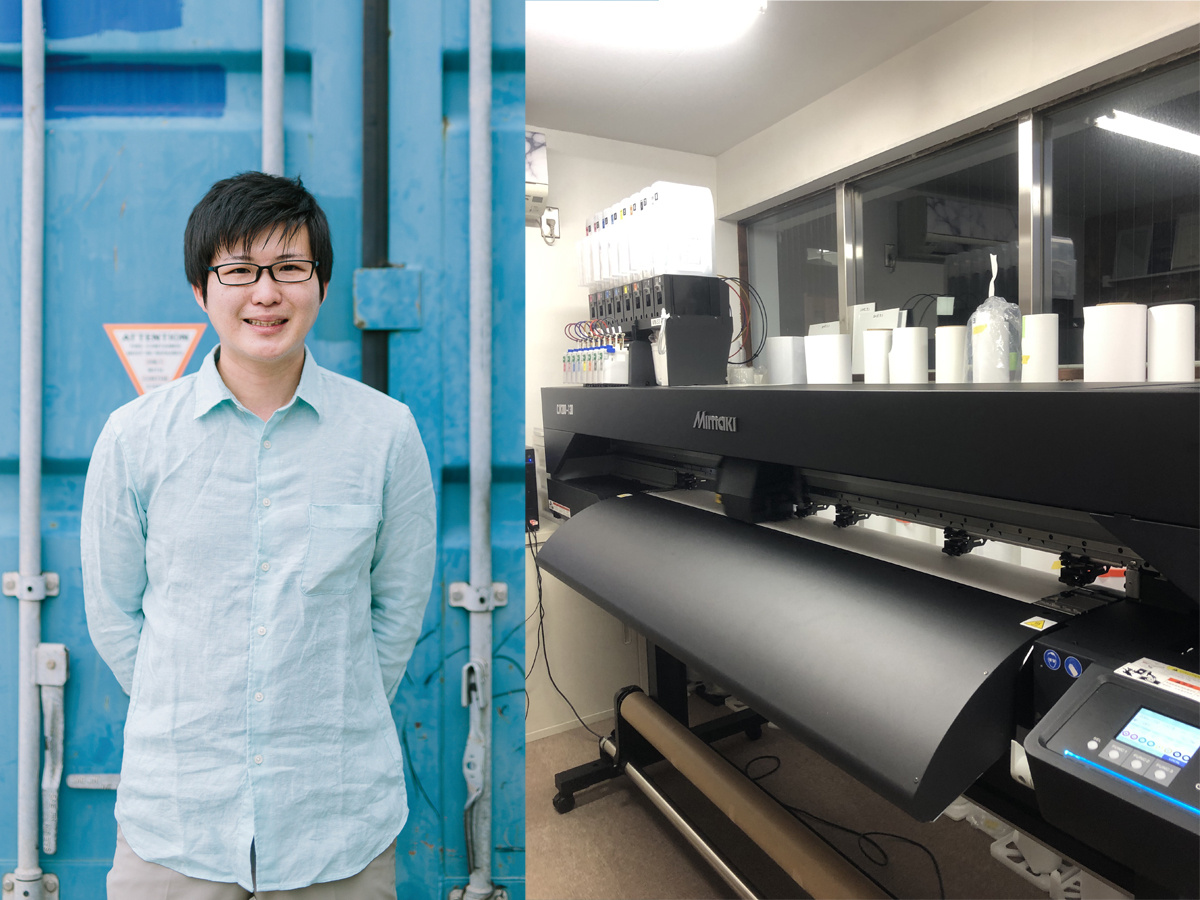

The Proven Performance of the "CJV200" Entry Model, Combining High-Quality Output and Ease of Use:SAN GRAPHICA Inc.Mimaki user stories

Challenges

Improvements

At SAN GRAPHICA Inc., while the "CJV300" had delivered high-quality printing, the expanding range of production materials necessitated more stable high-resolution output and improved workflow efficiency. Additionally, the ability to operate within limited installation space and the ease of operation and manageability even with a small staff were key points when considering equipment upgrades.

The introduction of the "CJV200" maintains the same high image quality while further improving color reproduction and detail stability. Its compact size and simple operation allow it to fit seamlessly into any workspace, streamlining daily tasks. Furthermore, low-odor ink and a system for monitoring operational status create an environment where even small teams can operate with confidence.

Product installed

Collaboration

Efforts of Mimaki

Support ski jumper Sara Takanashi with merchandise made using UV-DTF printers!

We printed the "JUMP for the Earth PROJECT" logo on a ready-made tumbler using the UV-DTF printer "UJV300DTF-75" and presented them to Sara Takanashi.

Product used